Composites

Ever since the invention of composites in 1500 BC, we have found ways to incorporate them in various designs. The modern age composites industry matured during the 1970s with a sudden boom in ingenious applications of such materials in varied fields such as from space technology to drink bottles. As the need to create energy efficient, durable and inexpensive designs increase; the composites are poised to make greater in-roads into various industries in the coming decade. With the help of the CAE framework, the design and analysis of such components has never been simpler or more efficient.

BETA CAE Systems recognizes the mutual benefit for supporting the composite industry in this endeavor and it provides various tools to handle CAE modeling & analyze results for simulations.

Solution Highlights:

- ANSA’s topology and meshing engines are best suited to take a solid CAD of a FRP sheet based models to its Finite Element representations.

- The fully automatic mid – surface generator for cast and plastic mold parts has greatly reduced time taken to get models with accurate thickness information and geometry.

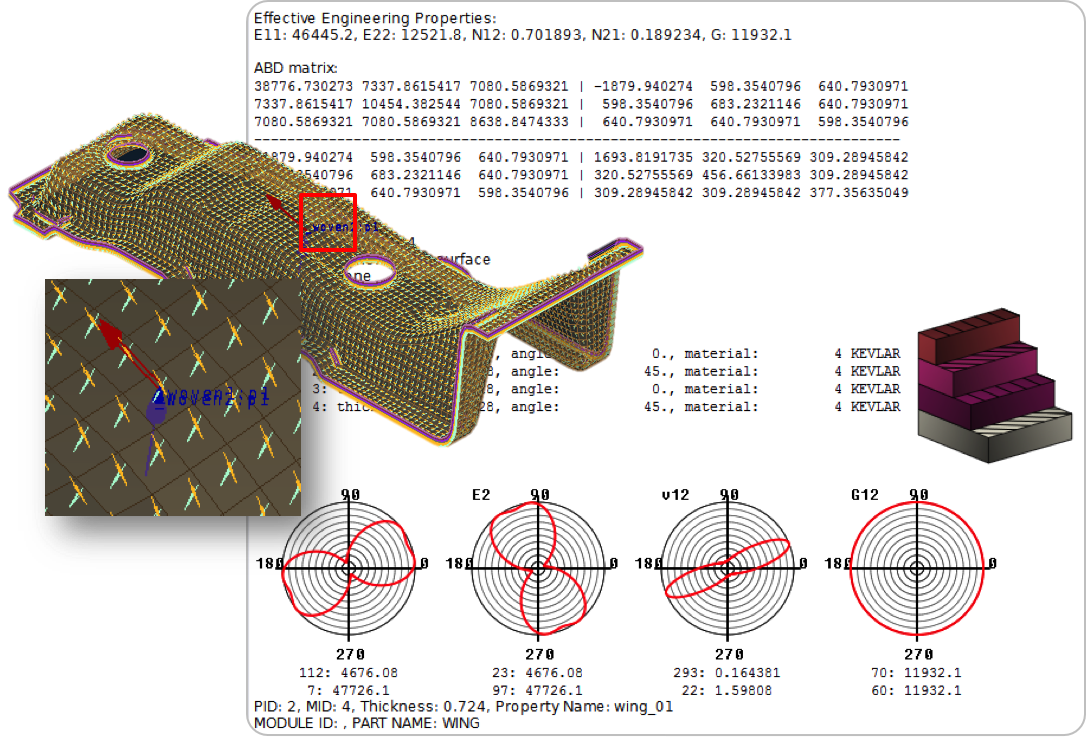

- ANSA has incorporated a unique Laminates Tool that handles all functions required by engineers & designers to model various parameters of composite components. This tool facilitates bi-directional data transfer between designers and CAE analysts to enhance collaborative efforts in product development.

- The tool has the ability to create & maintain multiple layers and sequences. It provides ability to incorporate layer thickness, layer orientation. User can also import such data from other simulation runs such as from FIBERSIM, or CAD based outputs using ANSA’s result mapping technology. The tool is also able to define and out accurate solid composite definition in various solver formats.

- The draping tool is also included in the tool. It is based on the fishnet algorithm and the user is now able to simulate to change and incorporate accurate thickness changes on the fly during model build. This eliminates the need for computationally expensive simulations.

- The tool is able to visualize the material orientation, element thickness and drape directions and modifications which helps to track changes to the model and builds accuracy into the modeling process.

- The laminate tool is solver independent and is able to accurately output appropriate keywords for multiple solvers such as NASTRAN™, ABAQUS, & DYNA among others, thus eliminating the need to maintain individual databases for each and thus reducing the logistics involved in model management in design process.

- The optimization task manager along with the morphing capabilities if ANSA provides user with a toolset capable to create shape and parameter – based optimization simulation. The user is able to parameterize any of the laminate layer components or use morphing to bring about shape changes in combination to generate optimized designs that are very close to manufacturability.

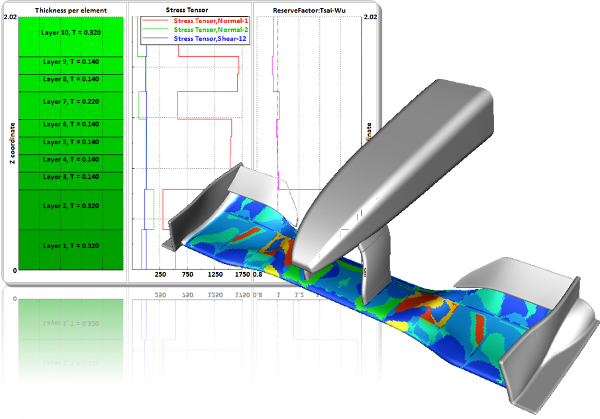

- META has a pre–installed toolbar to handle all post – processing work involved in composites. Some of the major features are:

- Identification of layers are describe in pre – processing steps.

- Calculation of Failure Criteria, Reserve Factors & Effort (Tsai – Wu, Puck, etc;)

- Identification of areas of Max. failure, critical directions, Failed elements.

- Ability to Plot stress tensors across each element thickness.

- Ability to re-evaluation of failure criteria within META interface after modifying material properties without the need for reanalysis.

- Support for simulation results from PERMAS™, NASTRAN™, ABAQUS™, LS-DYNA™